AUPE Headquarters: 3D Design Centered on Health & Wellness

backBy Aynsley Dueck, Duxton Windows & Doors

With contributions from AUPE and NEXT Architecture

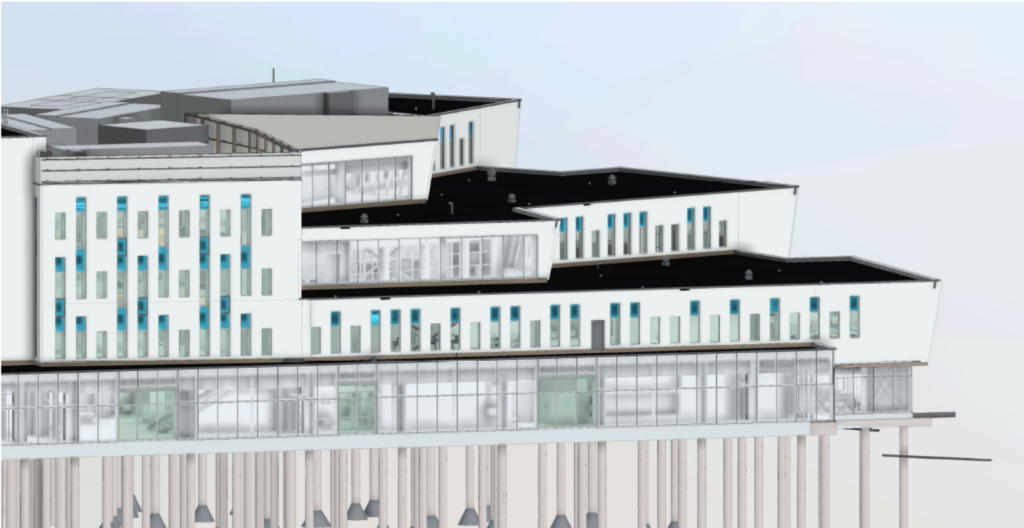

Edmonton’s AUPE (Alberta Union of Provincial Employees) headquarters stands as a beacon of modern office building innovation. It seamlessly integrates striking architecture with outstanding energy efficiency and occupant well-being. This pioneering structure is Edmonton’s first commercial office building to incorporate NECB 2011, WELL Building Standard, and LEED v4 into its design.

Sustainable Design from the Start

Next Architecture was carefully selected as the prime architecture firm due to its creativity, collaborative nature, and responsiveness to the client’s goals. Together, they developed the 125,000-square-foot headquarters, prioritizing sustainability and occupant health, all while pioneering the use of 3D design tools.

The Building Information Modeling (BIM) system was crucial in the planning, bidding, and construction phases. This technology allowed the architects to explore various design options, optimizing factors like floor layouts, orientation, solar heat gain, and energy use. BIM also streamlined construction by enabling the prefabrication of building components and accelerating on-site assembly.

“BIM helps optimize energy usage at the design phase,” comments Scott Hawryluk of Next Architecture. “This is especially valuable in the long run, as the typical building owner will spend five times the construction cost on maintaining the building.”

The 3D model further allowed trades to manufacture from the Revit models and prepare the mechanical, electrical, curtain wall, wall panels, plumbing, and fiberglass punched windows off-site. The modular exterior wall panels expedited construction by approximately 4-6 months.

Shown Above: 3D Renderings by NEXT Architecture

Watch the impressive time-lapse.

From Living Walls to High-Tech Systems

From a living wall that includes over 1,000 plants to smart building systems that adjust CO2 levels and temperature in real-time, the AUPE headquarters integrates numerous features to promote occupant well-being and environmental sustainability. The WELL Standard was particularly impactful, with thoughtful designs such as:

- The stairs are centrally located, and the elevator is hidden around the corner to encourage more active living.

- The vending machine offers healthier options.

- Water fountains are available throughout the building.

- Ample fresh air. The new building exceeded the fresh air requirement thanks to the WELL standards, which was particularly important during the COVID-19 pandemic.

“The AUPE building has an impressive operating system exclusively for controlling mechanical, lighting, CO2, temperatures, and security, to name a few,” comments Mike Moskaluk of AUPE. The dashboard is easily accessed so that any adjustments can be made remotely. The sensors in the building collect data constantly so that we can fine-tune the systems and bring down utility costs.”

A Clever Window Solution for Modular Panels

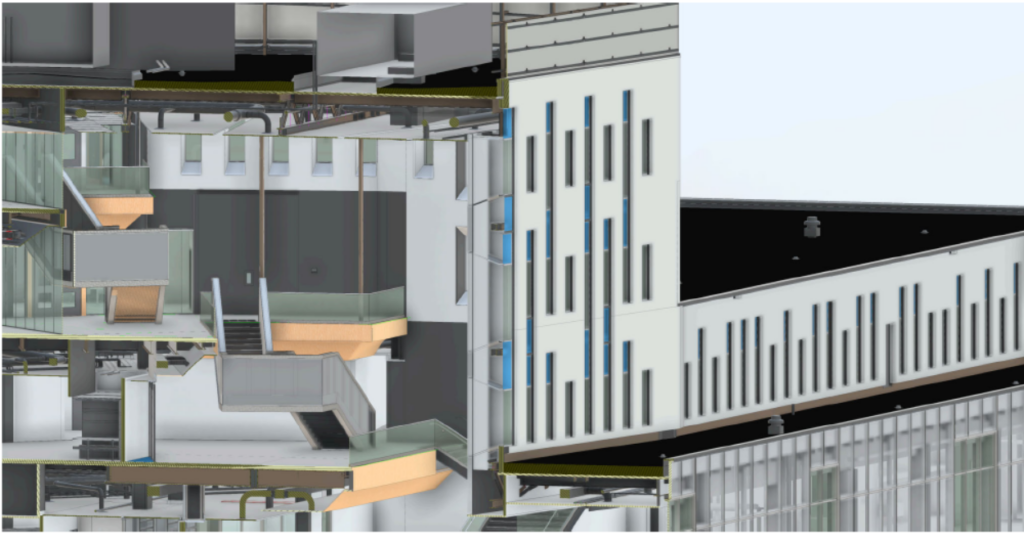

The designers at Next Architecture had decided to pursue modular panels for the building but needed a solution for the windows. The building design features vertical strip windows spanning multiple stories, so an aluminum curtain wall would normally be specified. However, a curtain wall would have the glazing installed on-site instead of in the modular panel factory. The designers wanted to avoid extending the construction timelines and added costs associated with the curtain wall option.

Aesthetics Meet Functionality

Next started looking at fiberglass frames because they are lighter and highly energy efficient. Upon approaching Duxton Windows & Doors, they communicated the goal of wanting factory-installed windows for each 2-story modular panel with minimal site work.

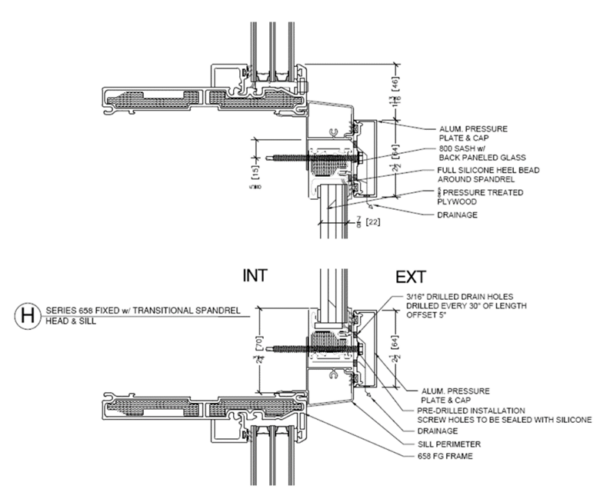

Duxton proposed a custom Transitional Spandrel to maintain the architectural integrity while achieving the construction goals. The windows were fabricated as punched openings and installed in the modular panel factory. Then, the Transitional Spandrel was installed on-site to create the illusion of continuous glazing.

Shown Above: FiberWall™ Series 658 Fixed Windows with Cardinal LoE-272 Insulating Glass, Sill Perimeter, and Custom Transitional Spandrel supplied by DUXTON Windows & Doors.

Unlike traditional stick framing, these modular panels and fiberglass windows facilitated faster assembly and installation, saving time and costs. Notably, the modular approach ensured a weather-tight building envelope much sooner, which is crucial for Edmonton’s climate.

The window design featured a few other clever details from NEXT Architecture:

- The narrow rectangular design helped meet the WELL standards for occupant well-being, as they push more daylight into the inner spaces.

- The deep window sills were angled at 45 degrees to reduce cleaning maintenance, as dust can’t stick to the drywall at that angle.

- A beautiful blue spandrel colour was selected to reflect the sky.

Shown Above: AUPE Building with Punched Openings and Transitional Spandrel Image Credit – Next Architecture

Shown Above: AUPE Interior Building with Punched Openings Image Credit – Next Architecture

Technological Collaboration for a Sustainable Future

The AUPE headquarters exemplifies the power of technological collaboration. Duxton collaborated with Next Architecture to create Revit models of their products, enhancing drawing accuracy and coordination among different trades.

Aynsley Dueck, Operations Manager at Duxton Windows & Doors, commented on this collaboration: “Scott Hawryluk from Next Architecture has been a trailblazer in BIM. It takes leadership to get trades away from 2D paper drawings and encourage everyone to adopt today’s 3D technology. We were very excited to publish our window Revit models and expect the technology to continue growing in use since it produces more accurate drawings, better coordination amongst trades, and has the potential to generate energy modeling in the future.”

A Model for the Future

Next Architecture’s collaborative design process resulted in a highly thoughtful design, putting “people first” at every stage. Combining the 3D model and prefabricated components substantially reduced construction timelines and costs and created a smooth construction process. The finished product is a long-lasting building that allows owners to conveniently monitor and manage energy usage. AUPE headquarters showcases a great commitment to innovation, energy efficiency, and quality. The project serves as a prototype for modern office buildings, demonstrating how clever planning and collaboration can elevate both functionality and sustainability.

For a closer look at the project’s stunning visuals and insights, visit Next Architecture’s project page.